Rear Sets and Levers – Wrap Up

This small project is a good example of how working with a prototype shop can quickly bring a design into reality while accommodating design changes along the way.

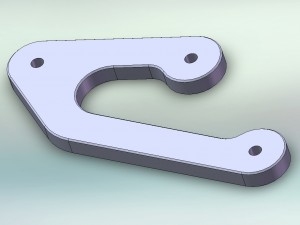

For those who are not familiar with racing motorcycles, the bracket shown is a “rear set” which moves the foot pegs back to allow the rider to get into a more aerodynamic position. Custom levers are required allow the rider to shift and activate the rear brake with his/her feet from the new peg location.

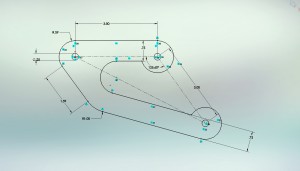

This project started with the client Frank Giannini giving us the distance between the threaded bosses on the motorcycle (to which the rear set would mount) and the amount of set back required.

Giannini also gave us an existing shift lever that used a pressed-in bearing. He wanted to use a snap ring to retain the bearing instead of the press fit. We generated Solidworks drawings of the rear set and levers and used HSMWORKS to generate the toolpaths for the CNC milling machine.

We machined one full set (a pair a rear sets and a pair of levers) and sent them to the client for a trial fit. Everything fit well on the first try. The only change requested was the reduction the size of the lightening holes in the levers to increase their durability. This was easily accomplished in Solidworks. Even major design changes (such as changing the length of the arms or the angle between them) would be easy at this point in the project.

With the design verified we ran off six more full sets for the race bikes and spares.

In a short amount of time we were able to start with a drawing and physical sample, generate a design and a prototype, revise the design based on feedback from the client and do a short production run.